M A T E R I A L S S C I E N C E d a s h b o a r d

U N T R E A T E D

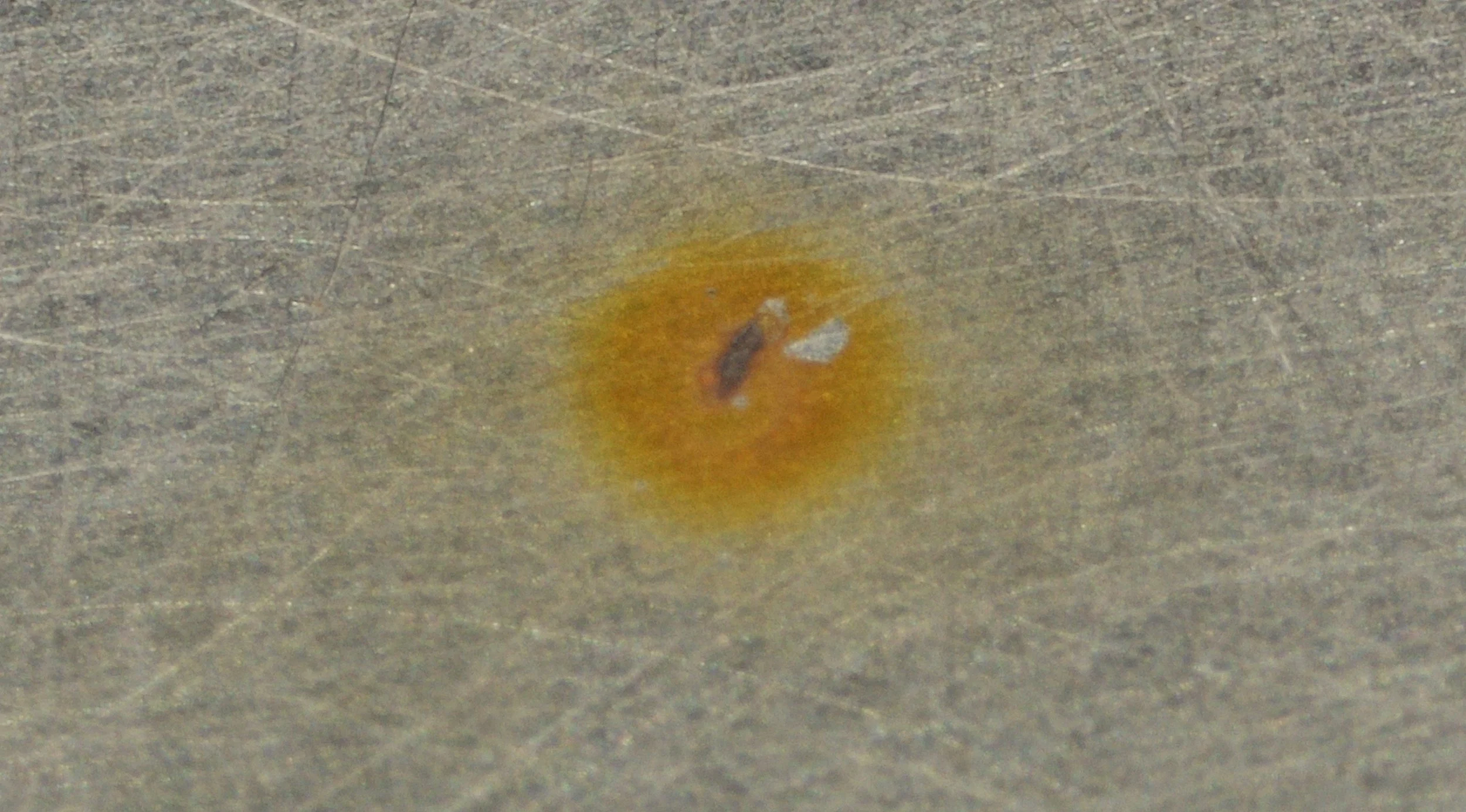

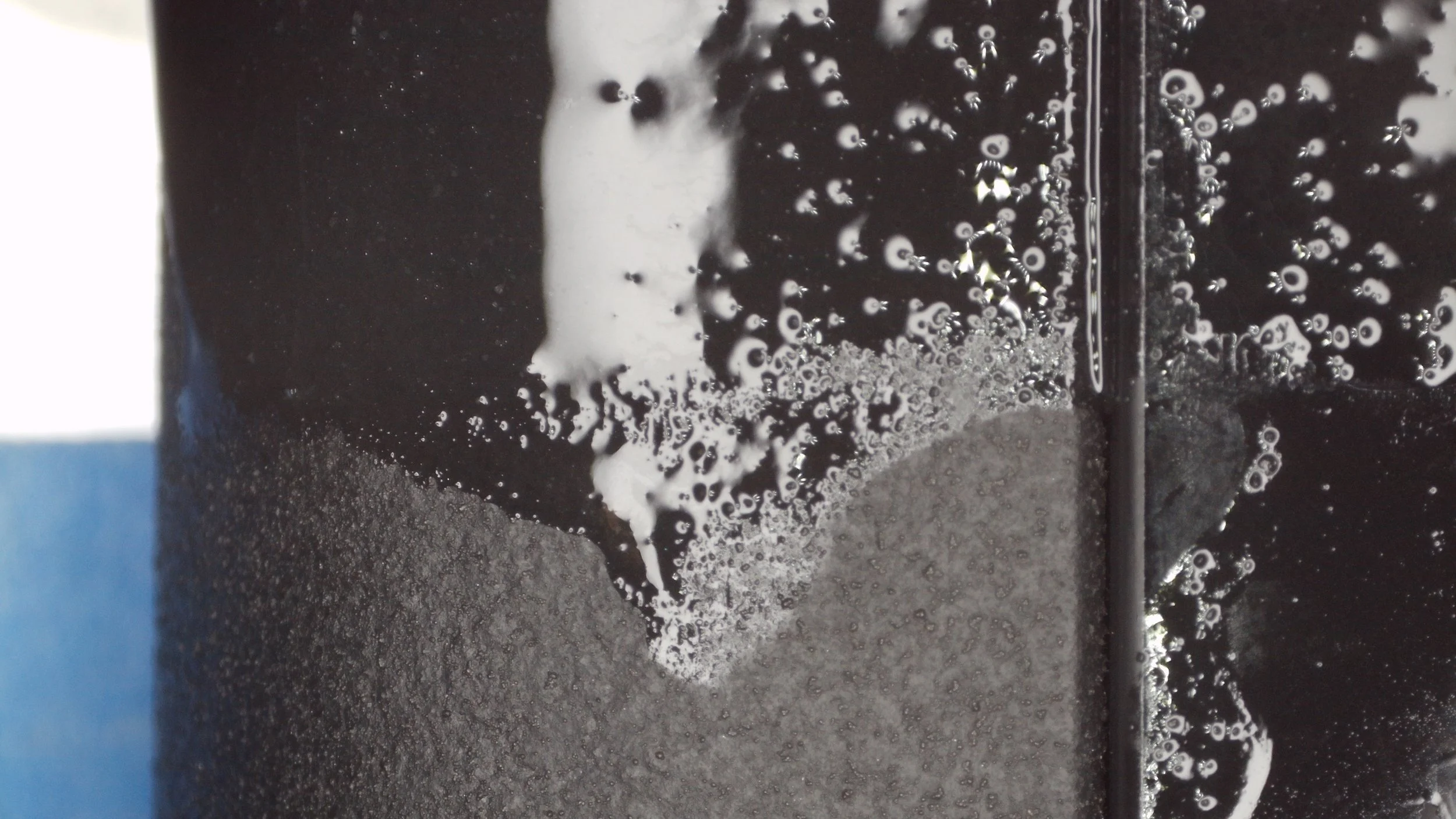

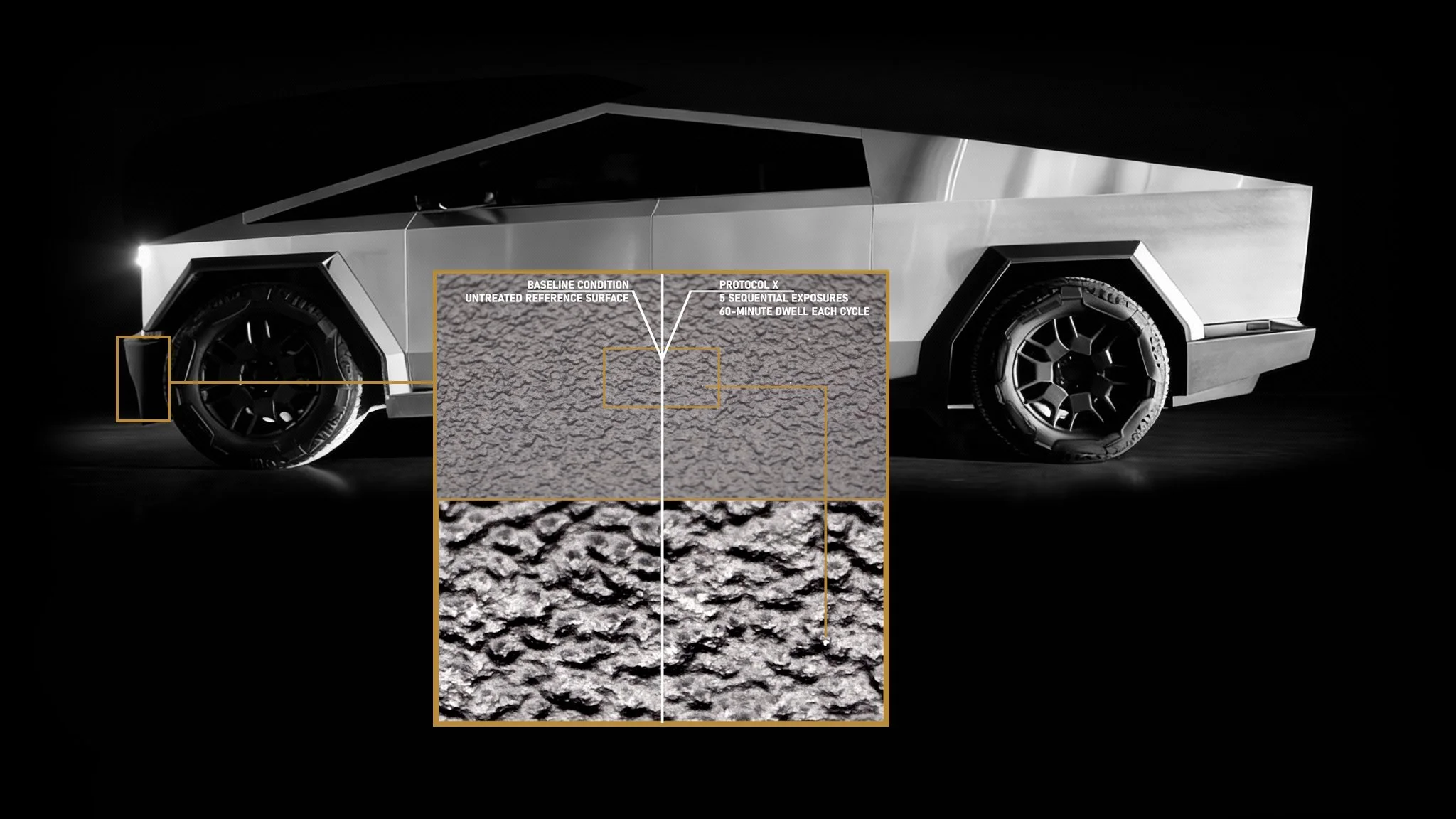

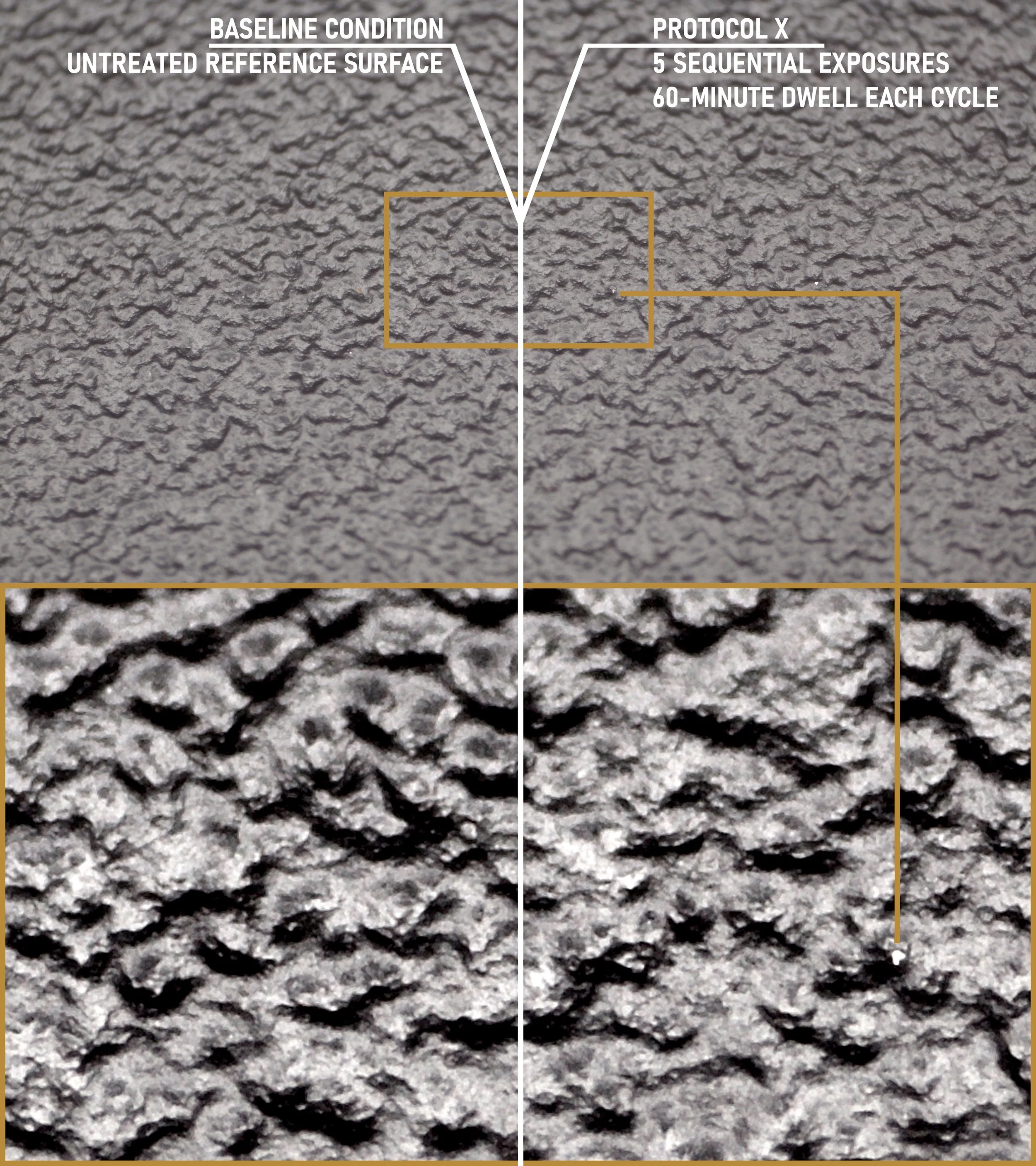

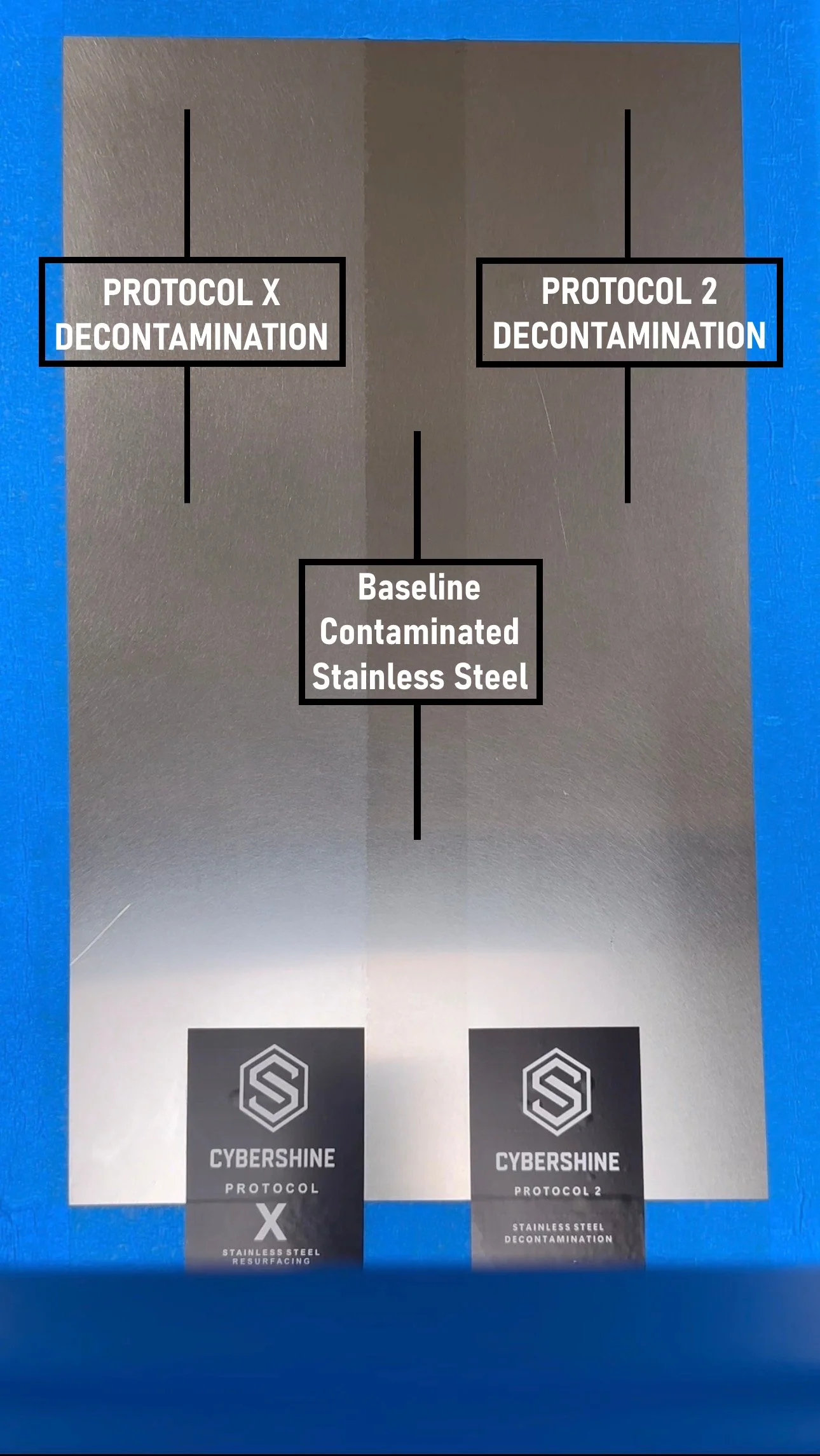

SURFACE STATUS – UNTREATED• Ferrous oxide accumulation (rouging)• Mineral scale embedded in microtexture• Organic road-film & polymerized deposits• Ionic contaminants (chloride / sulfate / alkali ions)• Passive-layer interference → reduced stability• Optical scatter → dull / beige cast• Surface heterogeneity → contrast drift & uneven reflectivityP R O T O C O L X T R E A T E D

• Complete removal of Fe²⁺/Fe³⁺ oxide films• Dissolution of Ca/Mg/silicate scaling• Neutralization of reactive ionic species• Passive-layer oxygen-exchange restored• Brightness increase (optical recovery, not gloss elevation)• Microtexture visibility restored → factory-matte silver• Uniform reflectivity without polishing or abrasion• Fully decontaminated stainless interfaceT E C H N I C A L N O T E S

OPTICAL RECOVERY INDEX: +17–28% (typical range)(Based on measurement of luminance delta between contaminated vs. clean microtexture)PASSIVE-LAYER INTEGRITY: PRESERVEDNo substrate brightening, grain alteration, or micro-abrasion.SURFACE RESET: COMPLETEChemical, ionic, mineral, and organic contaminants removed.P R O T O C O L X D E C O N T A M I N A T I O N R E S U L T S

P r o t o c o l X — S a f e t y & T e c h n i c a l O v e r v i e w

Validated for uncoated stainless steel architectures.Non-flammable • Non-corrosive • Industry-safe • Biodegradable Formula-

Product Name: CYBERSHINE PROTOCOL X – STAINLESS STEEL RESURFACING

Use: Corrective decontamination & resurfacing of uncoated stainless steel

Manufacturer: CYBERSHINE LLC - DISTRIBUTED BY DOWD INDUSTRIES LLC

-

GHS Classification:

• Non-flammable liquid

• Non-corrosive to skin

• Low VOC / low vapor pressure

• Not classified as carcinogenic, mutagenic, or reproductive hazard

• Not classified as hazardous wastePrimary Hazards:

• Mild eye irritation possible

• Prolonged skin contact may cause dryness

• Avoid ingestionRoutes of Exposure: Eyes / Skin (low hazard), Inhalation (negligible), Ingestion.

-

General Description:

Water-based chemical resurfacing system containing:

• Biodegradable chelating agents

• Surface-safe acid-base neutralizing components

• Non-ionic and amphoteric surfactant carriers

• Rinse aids and stabilizers

• No abrasives

• No volatile solvents

• No petroleum distillates

• No chromates or chlorinated agents

• No carcinogenic materials -

Eyes: Rinse with clean water for 10–15 minutes.

Skin: Wash with soap and water.

Inhalation: Not expected to cause irritation; move to fresh air if needed.

Ingestion: Rinse mouth; drink water; seek medical attention if large quantity consumed. -

Flash Point: Non-flammable

Vapors: Non-combustibleFire Behavior: Will not sustain combustion

Suitable Extinguishing Media: Water, foam, CO₂, or dry chemical

-

Personal Protection: Standard PPE (nitrile gloves, eyewear).

Environmental Precaution: Product is biodegradable; dilute with water.

Spill Response: Absorb with inert material; rinse area with water.

-

• Store between 40–95°F

• Keep container sealed when not in use

• Avoid freezing

• No special ventilation required

• Non-reactive with stainless steel, plastics, rubber, and glass

-

• Safety glasses recommended

• Nitrile gloves recommended

• Respiratory protection not required

• No special ventilation required -

Appearance: Clear to slightly hazy liquid

Odor: Mild / non-offensive

VOC Content: Very low (<2%)

pH: Mildly acidic

Boiling Point: ~100°C

Solubility: Completely water-soluble

Flammability: Non-flammable -

• Chemically stable

• No dangerous polymerization

• Avoid mixing with strong alkalis or oxidizers (not required in Tesla workflow) -

• Non-carcinogenic

• Non-mutagenic

• Non-sensitizing

• Low toxicity in all typical exposure pathways -

• Readily biodegradable

• Non-persistent in environment

• No aquatic toxicity expected at use dilution -

• Rinse to drain with water

• Follow local regulations (non-hazardous waste) -

• Not regulated as hazardous material

• No special handling requirements -

• Meets consumer and industrial safety guidelines

• Non-HazMat for DOT shipping

• No special labeling requirements -

Validated for use across Tesla’s uncoated stainless architecture and non harmful to surrounding exterior materials

MATERIAL COMPATIBILITY

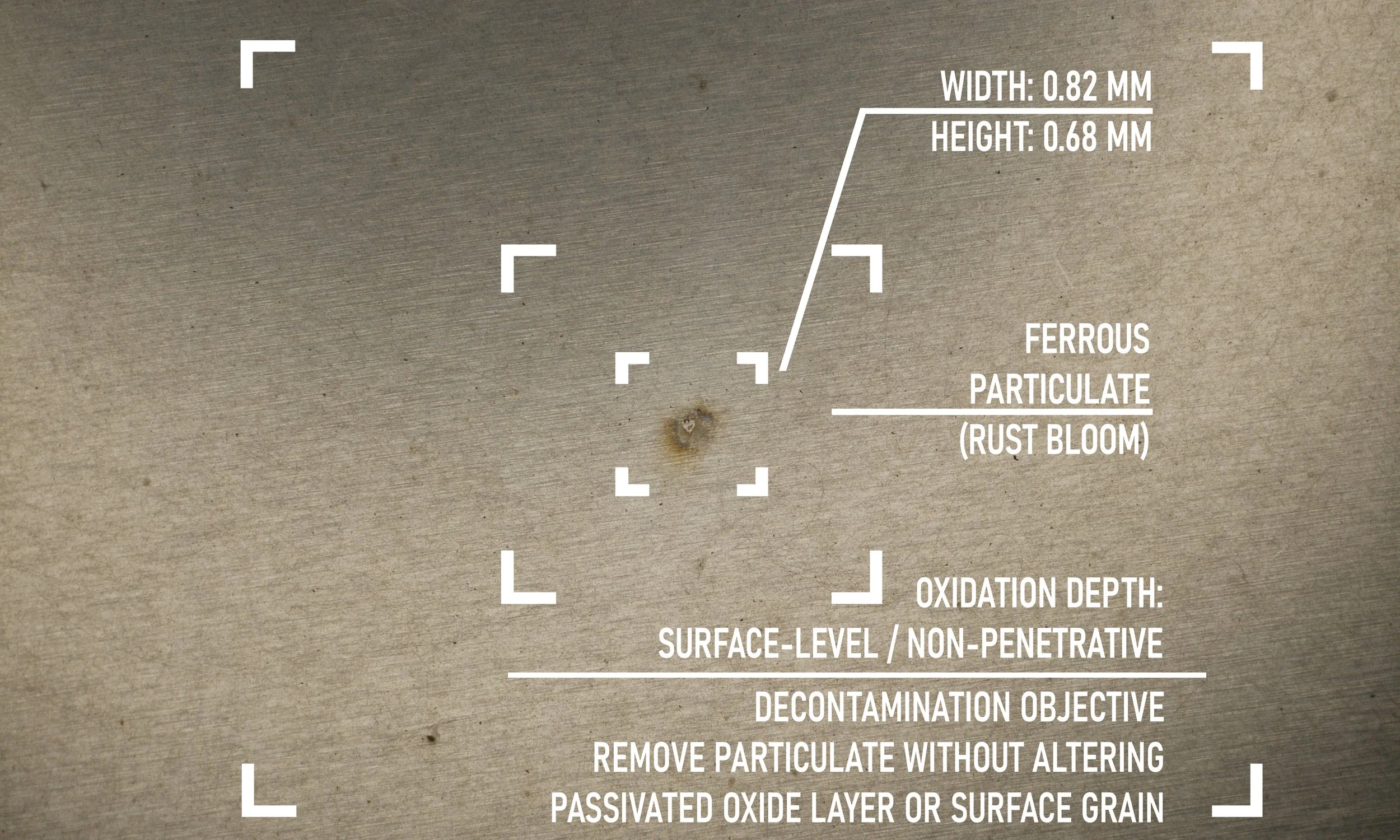

Cybertruck B-Pillar Exterior Glass • Cybertruck Perimeter Window Gasket (OEM SUBSTRATE) Full-concentration saturation exposure — static dwell Direct liquid contact (non-diluted Protocol X)SAMPLE SET: • 5 sequential exposures • 60-minute dwell each cycle • Zero mechanical agitation • Ambient 72 degree lab temperature.No visible, microscopic, structural, or chemical degradation observed on either substrate after aggressive stress-testing. B-PILLAR GLASS / WINDOW GASKET1000 X MAGNIFICATION - PROTOCOL X B-PILLAR GLASS / WINDOW GASKET1000 X MAGNIFICATION B-PILLAR GLASS / WINDOW GASKET2000 X MAGNIFICATIONE X P A N D E D L A B R E P O R T C L I C K T O V I E W F U L L A N A L Y S I S

-

TEST SERIES: Protocol X — Exterior Material Compatibility

Substrates:

• Cybertruck B-Pillar Exterior Glass

• Cybertruck Perimeter Window Gasket (OEM)Test Method:

Full-concentration Protocol X saturation, static dwell exposure

• 5 cycles

• 60 minutes each

• No mechanical agitation

• Ambient 72°F lab conditionsObjective:

Evaluate chemical compatibility, optical stability, and elastomer integrity under extreme over-exposure conditions.RESULTS — GLASS (B-PILLAR PANEL)

PASS — No Change Observed

Measured outcomes:

• No haze, pitting, or micro-etching

• No variance in surface energy

• OEM hydrophobic coating unaffected

• 1000×–2000× magnification: no micro-fractures, mineral scarring, or oxide shift

• No residual film — fully rinsableRESULTS — WINDOW GASKET (OEM)

PASS — No Change Observed

Measured outcomes:

• No color shift

• No swelling, softening, or tackiness

• No dimensional change or edge lifting

• No polymer breakdown or bleaching

• 1000×–2000× magnification: no fissures, matrix disruption, or surface rougheningCOMPATIBILITY SUMMARY

FULL COMPATIBILITY VERIFIED

No visible, microscopic, structural, or chemical degradation was observed on either substrate after aggressive repeated exposure.

Protocol X is confirmed safe for direct and repeated contact with Cybertruck exterior glass and gasket materials, consistent with Cybershine’s Material Compatibility Validation Program.TESLA SERVICE NOTES

• Approved for full-panel exterior applications

• Corrects acid etching, mineral spotting, ferrous deposition, and organic films

• Eliminates sanding, scraping, or panel replacement in most cases

• Compatible with: glass, rubber gaskets, trim, headlights/taillights, and painted aluminum touchpointsSTATUS: PASS — MATERIALS COMPATIBLE

ANALYSIS PREPARED FOR: TESLA

CYBERSHINE R&D LAB — PASADENA, TX

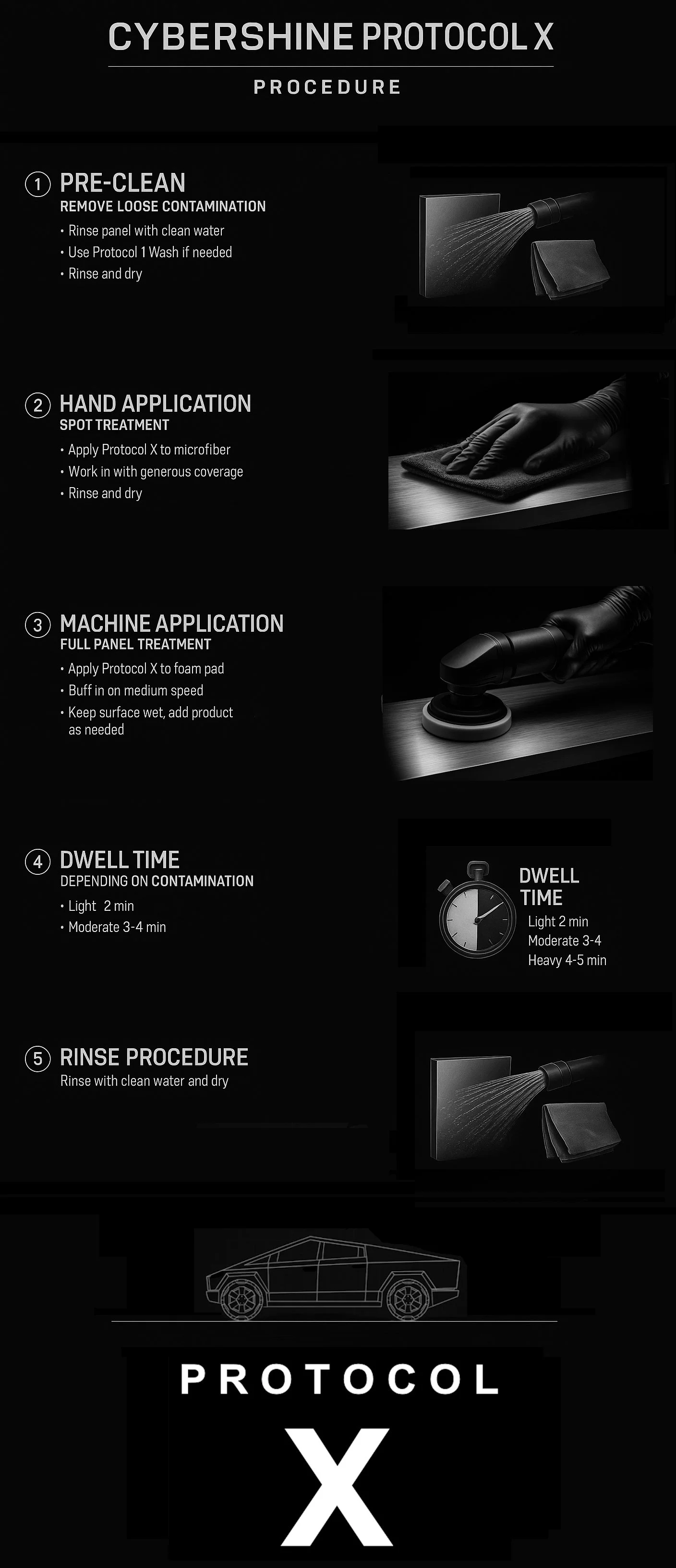

CYBERSHINE PROTOCOL X — TESLA SERVICE APPLICATION SOP

Purpose:

Protocol X is a stainless-safe chemical resurfacing system engineered to remove rouging, mineral deposits, water-spot etching, and bonded surface ions without sanding, polishing, or panel replacement. Restores OEM brightness and uniformity.APPROVED TOOLS

• Random orbital buffer

• Orange foam finishing pad

• Microfiber towels

• Clean water

• Nitrile gloves (optional)MATERIAL COMPATIBILITY

Protocol X is validated safe for all Cybertruck exterior materials, including stainless steel, plastic fenders, bumpers, rubber gaskets, glass, camera housings, headlights, and taillights.

Compatibility fully verified in Cybershine Materials Science Lab.APPLICATION METHODS:1. HAND APPLICATION (Spot Treatment)

Apply a generous amount of Protocol X to a microfiber towel.Spread evenly over the targeted area.Allow 2–5 minutes dwell depending on contamination level.Work into the surface for 2–4 minutes, keeping the area wet.Rinse with clean water and dry.Repeat if needed.

2. MACHINE APPLICATION (Recommended for Full Panels)

Apply a generous, wet coat of Protocol X directly to the orange foam pad.Spread product onto the surface before turning on the buffer.Start low to distribute, then run at medium–high speed.Make slow, overlapping passes, adding more product to maintain a wet surface.Allow 2–5 minutes dwell without letting the panel dry.Rinse thoroughly and dry.Reapply if required.

FULL-PANEL RECOMMENDATION

Protocol X brightens stainless during decontamination.

Treating only a spot can create visible differences.

Whenever possible, complete the entire panel (door, fender, bedside, frunk, etc.) for uniform appearance.DWELL TIME GUIDELINES

• Light water spots: ~2 min

• Moderate rouging: 3–4 min

• Heavy staining/etching: 4–5 min (may need multiple passes)RINSE PROCEDURE

Rinse the treated area with clean water, wipe dry with microfiber, and confirm all dissolved contamination is removed.WHEN TO USE PROTOCOL X

Use on panels exhibiting:

• Rust-colored rouging

• Water spot staining

• Acid etching

• Mineral deposits

• Dull or darkened appearance

• Surface film that does not wash offProtocol X often eliminates the need for sanding, abrasive polishing, warranty escalation, or panel replacement.

Typical correction time: 15–20 minutes per panel.SAFETY

• Non-flammable

• Low VOC

• No fumes

• Non-corrosive

• Skin-safe

• Fully safe on all Cybertruck exterior materialsFINAL RESULT

Protocol X restores stainless steel to a clean, bright, uniform finish, removes bonded contaminants at the oxide boundary, and preserves the original grain structure and passivation layer.PROTOCOL X / BEFORE AND AFTER RESULTS

HOW TO USE / PROTOCOL X

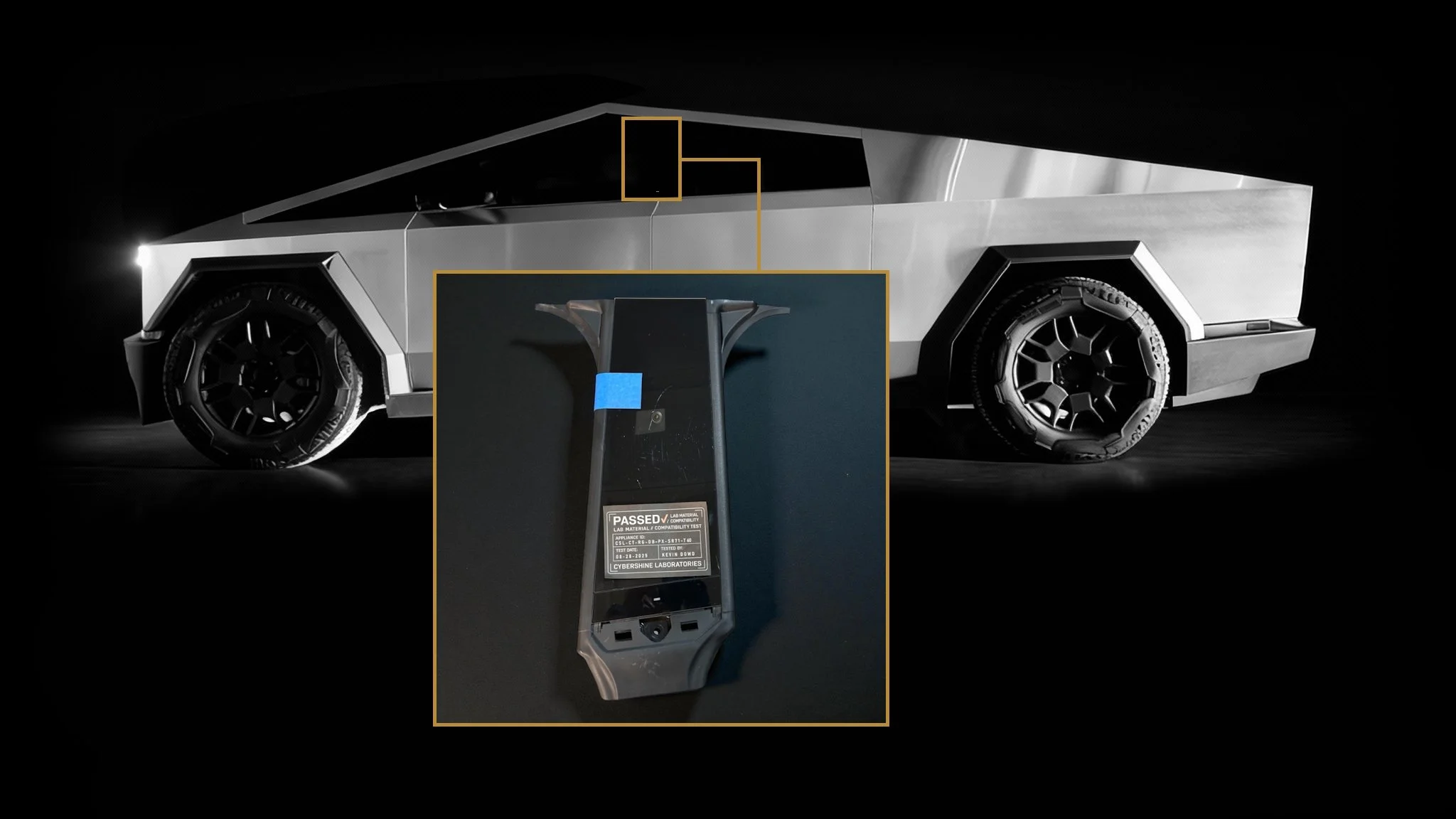

MATERIALS COMPATIBILITY — BLACK TRIM / BUMPER COVER

TEST SERIES: Protocol X — Exterior Polymer Compatibility

SUBSTRATES TESTED

• Cybertruck Black Exterior Trim (OEM polymer)

• Cybertruck Front/Rear Bumper Cover (OEM polymer blend)

These represent the major exterior black plastic components used throughout Cybertruck fascia, lower body, and rear bumper architecture.

TEST METHOD

Direct full-strength Protocol X saturation exposure

Static dwell method — repeated over-exposure cycles

Test parameters:

• 5 sequential exposure cycles

• 60-minute dwell per cycle

• Full-concentration, non-diluted Protocol X

• Zero mechanical agitation (no wiping, scrubbing, or pressure)

• Ambient 72°F Cybershine lab conditions

• Controlled drying prevention (surface maintained wet for full dwell duration)

This protocol simulates worst-case over-exposure, exceeding any real-world or Tesla service workflow conditions.

OBJECTIVE

Evaluate Protocol X’s chemical compatibility with Cybertruck’s exterior polymer components, focusing on:

• Color stability

• Surface texture integrity

• Structural and dimensional stability

• Polymer matrix resilience

• Microstructural behavior under 1000×–2000× magnification

• Resistance to softening, swelling, denaturing, or gloss disruption

RESULTS — BLACK EXTERIOR TRIM (OEM TRIM POLYMER)

PASS — NO CHANGE OBSERVED

Measured outcomes:

• Color Stability: No fading, darkening, or discoloration

• Surface Texture: No softening, tackiness, or increased friction

• Dimensional Stability: No swelling, warping, or edge deformation

• Gloss/Sheen: No increase or decrease in reflectivity

• Chemical Integrity: No polymer breakdown, denaturing, or bleaching

• Microscopy (1000×–2000×):

– No fissures

– No micro-pitting

– No matrix disruption

– No roughening or surface erosion

Residual Film: None — Protocol X remained fully rinsable with clean water.

RESULTS — BLACK BUMPER COVER (OEM POLYMER BLEND)

PASS — NO CHANGE OBSERVED

Measured outcomes:

• Color Stability: Identical before/after values

• Surface Hardness: No change in durometer or surface rigidity

• Texture Consistency: No smoothing, no etching, and no micro-abrasion

• Dimensional Integrity: No shrinkage or distortion after prolonged dwell

• Chemical Resistance: No bleaching, no oxidation, no plasticizer disruption

• Microscopy (1000×–2000×):

– Uniform polymer matrix

– No micro-cracking

– No pore enlargement

– No residue lodged in microstructure

Residual Film: None — fully rinsable with clean water.

COMPATIBILITY SUMMARY

FULL COMPATIBILITY VERIFIED

After five 60-minute over-exposure cycles, no visible, structural, chemical, or microscopic degradation was observed on either substrate.

Protocol X is confirmed safe for:

• Full-panel Cybertruck applications

• Direct contact with all external polymer trim

• Repeated service-use exposure

• Use during decontamination, resurfacing, and corrective workflows

These findings align with Cybershine’s broader Material Compatibility Validation Program, verifying cross-material safety across steel, glass, elastomers, and exterior polymer composites.

TESLA SERVICE NOTES

• Protocol X is approved for use around all Cybertruck exterior trim and polymer components

• Incidental contact is fully safe; rinse with clean water

• Does not cause fading, chalking, gloss shift, or texture disruption

• Enables correction of contamination near trim without risk to polymer surfaces

• Eliminates need for sanding, heat guns, abrasives, or chemical neutralizers

• Ideal for resolving:

– Acid etching

– Mineral spots

– Industrial fallout

– Environmental surface films

STATUS: PASS — MATERIALS COMPATIBLE

ANALYSIS PREPARED FOR: TESLA

CYBERSHINE R&D LAB — PASADENA, TX

2 0 0 0 X M A G N I F I C A T I O N

P r o t o c o l X

Protocol X is a non-abrasive chemical resurfacing system developed to restore Tesla Cybertruck stainless steel to its factory-original matte appearance by removing bonded contamination, mineral scaling, ferrous oxide films, ionic residues, and organic deposition—without altering substrate grain or increasing gloss.

The system is safe, non-flammable, low-VOC, non-carcinogenic, readily biodegradable, and fully compatible with Tesla’s uncoated stainless architecture and surrounding exterior materials.

Through coordinated reduction, chelation, complexation, and ionic neutralization mechanisms, Protocol X resets the stainless-steel interface at the chemical and optical level. The treatment preserves the chromium-oxide passive layer while clearing all foreign films that interfere with passive regeneration, enabling the stainless surface to recover stability and resist future rouging.

Unlike polishing or abrasive brightening, Protocol X increases apparent brightness by restoring stainless steel to its true, uncontaminated optical state—removing darkening films such as iron, mineral scale, polymerized residues, and atmospheric deposits that accumulate over time.

The result is a uniform, brighter, factory-correct silver finish with zero gloss elevation and zero microtexture modification.

Fully rinsible, fully surface-neutral, and validated for Tesla stainless steel.

P R O T O C O L 2

-

Surface Characteristics:

Embedded metallic particles

Organic and inorganic film layers

Mineral deposits from water exposure

Early-stage oxidation (rouging)

Reduced brightness and non-uniform reflectivity

Impact:

Grain shadowing

Dull appearance

Increased surface distortion

-

What Protocol 2 Does

1. Lifts metal-linked contamination

Breaks down contamination attached to the surface, including:

iron particles

environmental metal buildup

mineral deposits

early-stage oxidation layers

2. Removes film thickness that distorts reflectivity

Releases:

road film

oils and grease

hydrocarbons

atmospheric residue

3. Controlled micro-phase assistance (non-scratch)

Helps detach bonded contamination that resists chemical cleaning

Smooths interference points

Does not disturb stainless-steel grain

4. Enhanced drying and residue release

Reduces streaking

Improves cleaning efficiency

Enhances clarity

5. Stable surface contact

Holds active cleaning agents in place

Ensures uniform decontamination

Outcome:

A clean, bright surface with grain preserved; ideal for routine and moderate contamination.

-

What Protocol X Does

1. Removes oxidation (rouging) and deeper surface films

Breaks down the oxide layers that:

suppress brightness

create brownish/gray discoloration

accumulate within grain valleys

2. Releases bonded metallic contamination

Targets contamination responsible for grain shadowing:

embedded iron

brake/rail dust

industrial particulates

3. Dissolves microfilms that distort light reflectivity

Lifts:

hydrocarbons

oils

atmospheric residues

film layers that dull the surface

4. Supports stainless-steel passivation

By clearing contaminants that inhibit chromium oxide regeneration, the surface is able to:

stabilize its natural protective layer

resist future discoloration

maintain long-term clarity

5. Fully non-abrasive

No mechanical action

No change to grain alignment

No impact on surface topography

Outcome:

Higher brightness, deeper clarity, improved reflectivity, and stabilization of natural passivation — ideal for persistent contamination and oxide films.

FOR ASSISTANCE PLEASE TEXT OR CALL CYBERSHINE HQ AT